金属外壳之油封

一般均作表面研磨以达密封之效果。

橡胶外壳油封

尤其使用在铝、铜及陶瓷等较脆弱之配套孔其效果更佳。

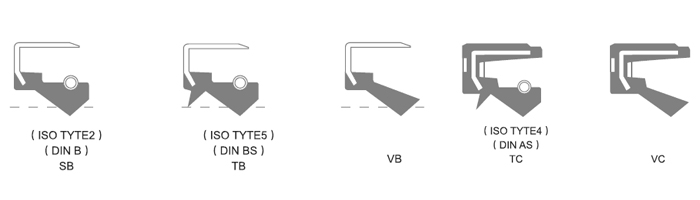

备注:1、SB/TB/VB型之油封依据客人之订单生产。

2、TC油封(NBR70)有现货供应。

骨架油封尺寸标示及公差标准

| ISO/R286 H8 |

GB9877.1-88 |

||||

|

轴径及孔径之名义尺寸 |

油封配套孔径之公差 |

油封配套轴径之公差 |

配合轴径大于至 |

主唇口公差 |

副唇口公差 |

|

6.00 TO 10.00 |

-0.000/+0.020 |

+0.000/-0.090 |

5-30 |

-0.5/-1.3 |

-0.15/-0.45 |

|

10.01 TO 18.00 |

-0.000/+0.027 |

+0.000/-0.110 |

30-60 |

-0.8/-1.7 |

-2.0/-0.60 |

|

18.01 TO 30.00 |

-0.000/+0.033 |

+0.000/-0.130 |

60-80 |

-1.0/-2.0 |

-0.25/-0.75 |

|

30.01 TO 50.00 |

-0.000/+0.039 |

+0.000/-0.160 |

80-130 |

-1.2/-2.6 |

-3.0/-0.90 |

|

50.01 TO 80.00 |

-0.000/+0.046 |

+0.000/-0.190 |

130-250 |

-1.5/-3.3 |

-0.40/-1.05 |

|

80.01 TO 120.00 |

-0.000/+0.054 |

+0.000/-0.220 |

250-400 |

-2.0/-4.0 |

-0.50/-1.30 |

|

120.01 TO 180.00 |

-0.000/+0.063 |

+0.000/-0.250 |

|

|

|

|

180.01 TO 250.00 |

-0.000/+0.072 |

+0.000/-0.290 |

|

|

|

|

250.01 TO 315.00 |

-0.000/+0.081 |

+0.000/-0.320 |

|

|

|

|

315.01 TO 400.00 |

-0.000/+0.089 |

+0.000/-0.360 |

|

|

|

|

400.01 TO 500.00 |

-0.000/+0.097 |

+0.000/-0.400 |

|

|

|

|

GB13871-92 |

||||||

|

尺寸(外径)大于至 |

外露骨架型(外径公差) |

内包骨架型(外径公差) |

外露骨架型(圆度公差) |

内包骨架型(圆度公差) |

高度公差 |

|

|

≤10 |

≥10 |

|||||

|

50以下(含50) |

+0.20/+0.08 |

+0.30/+0.15 |

0.18 |

0.25 |

±0.3 |

±0.4 |

|

50-80 |

+0.23/+0.09 |

+0.35/+0.20 |

0.25 |

0.35 |

±0.3 |

±0.4 |

|

80-120 |

+0.25/+0.10 |

+0.35(0.45)/+0.2 |

0.30 |

0.50 |

±0.3 |

±0.4 |

|

120-180 |

+0.28/+0.12 |

+0.45(0.50)/+0.25 |

0.40 |

0.65 |

±0.3 |

±0.4 |

|

180-300 |

+0.35/+0.15 |

+0.45(0.55)/+0.25 |

外径的0.25% |

0.80 |

±0.3 |

±0.4 |

|

300-440 |

+0.45/+0.20 |

+0.55(0.65)/+0.30 |

外径的0.25%, |

1.00 |

±0.3 |

±0.4 |

*SN70-TC00501506BA *TC=产品型式 *S=骨架油封 *005=内径 *N=NBR(参照材料物性表) *015=外口 *70=70邵氏度(材料硬度) *06=高度